Hello!

We’ve covered quite a few things so far as part of the “Painter in Your Pocket” series, but this topic is probably the one where I get the most questions. What kind of sprayer do I need? Will I be able to use it? Will it give me a smooth finish? How much will it cost? Lots of questions, and I’m hoping to answer them, while also sharing some paint sprayers that I have had the opportunity to use.

There are a lot of different paint sprayers on the market, and the choices can certainly be a bit overwhelming and intimidating. The prices can be all over the map, and I know I did a lot of research and reading when I decided to purchase my first paint sprayer, so I’ve been there. I’m hoping you can learn from my personal experience.

Given that there is so much to cover, I’m going to break this topic down into a couple of posts, so that this post doesn’t get to be too overwhelming for your sake, and for my own. Are you ready to get started? I have had this post written up and in progress for more than a month now, and I’m just going to put it out there, cross my fingers, and hope that you find this first installment helpful. 🙂 This post contains some affiliate links to products that I know and use from experience, and trust them in the work that I do.

HVLP Conversion Guns

If you read my blog regularly, you know that my primary focus is on kitchen cabinets and furniture pieces, so I was looking for a sprayer with that purpose in mind. Granted, things have grown and changed over time, and my sprayer has changed along with it. For the sake of context, let’s talk about my first sprayer – my trusty Wagner HVLP conversion gun.

This was a great way to enter into the world of HVLP (High Volume Low Pressure) paint sprayers, and it’s the gun that I used when I painted my kitchen cabinets. I found it really easy to use, reasonably priced, and the end result was nothing short of fantastic. My cabinets look like they were factory finished, and this is the spray gun that made it happen. If I can figure out how to use this tool, you most certainly can.

How to Use It

This gun requires that you have an air compressor (which we already had – a six gallon Bostitch), and you can see that there is a regulator at the bottom of the handle (the round thing that looks like a gauge, if that helps). This is where you adjust the air pressure – but other than that, it is very similar to my newer paint sprayer (an HVLP turbine system, which eliminates the need for an air compressor, but more on that later). Here is the air compressor that I used with my Wagner HVLP Conversion Gun.

It’s your basic 6 gallon compressor, 150 PSI, 3.7 CFM@40PSI, 2.8CFM@90PSI. CFM stands for cubic feet (per) minute, and it is relevant because it directly relates to the suitability of a compressor for a given application. I used this compressor with my conversion gun and it worked like a charm. I wouldn’t go any smaller, but you could certainly go larger without an issue either. They don’t make this exact compressor anymore, but there are plenty of six gallon air compressors to choose from here.

Much of learning how to use a paint sprayer is through trial and error. With the HVLP conversion gun setup, you need to set the pressure at the air compressor (according to the directions – but if memory serves, I increased the pressure on mine a wee bit. (Again, trial and error). Then you set the pressure at the regulator on the spray gun itself (according to instructions). Then, when you’re getting ready to spray, you need to adjust the material flow (which controls how much paint comes out of the gun).

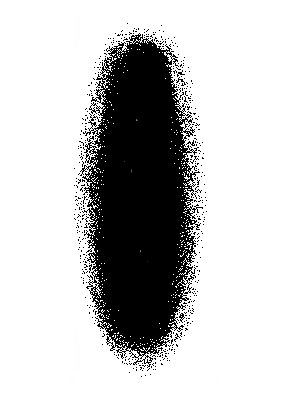

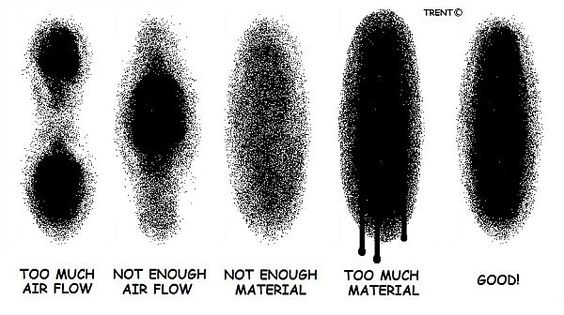

The round tip of the gun controls the fan pattern – whether it’s a horizontal, vertical or circular pattern, and you can also control the size of your spray pattern. I suggest practicing on a piece of cardboard or something like that, so you can experiment with the settings and what the resulting spray pattern looks like. Here is a great guide to what your spray pattern should and should not look like, while also identifying what the issue is so that you can adjust.

Here’s what your spray pattern should look like:

Here is a chart that can help you troubleshoot your spraying if you’re having issues:

HVLP Turbine Systems

The HVLP conversion gun served me well for quite a long time – I painted our kitchen cabinets with it, as well as those for several clients. Once I started getting a more regular flow of new kitchen jobs, and knew that I was going to continue to grow, I decided it was time for an upgrade, and purchased a Titan Capspray HVLP Turbine system (mine is the Titan Capspray 95).

The beauty of this setup is that you no longer have to worry about using an air compressor, and there is no regulator on the gun itself. Everything is all contained in one unit. The turbine delivers a constant flow of power and pressure to the gun and you only have to worry yourself with adjusting the air flow and the material flow at the gun level (that would be the two little knobs at the top of the gun). See? All streamlined.

I’m speaking about the Titan Capspray, because this is the gun that I use and graduated to after using the HVLP Conversion gun. There are other options out there that I’ve seen and I know people use and are happy with them. A comparable turbine setup to the one that I have, would be this one from Graco. I will have to see if I can get my hands on some Graco sprayers to give them a whirl, because I know they’re out there and available as an option.

Again, I’m putting this out there because it’s an option, but I don’t have any personal experience using it.

Keep in mind that turbine systems are an investment. Had I not continued doing kitchen cabinet jobs, I would have carried on with my trusty HVLP Conversion Gun. That said, I love this piece of equipment, and it has paid for itself many times over, and I have put it to task. It’s a work horse, and has really been pretty low maintenance overall. I have replaced some filters, and I bought a new hose, but that’s pretty much it. I did buy another gun, but that was for my own convenience, to have more than one on hand.

If you did make this kind of investment, I would also recommend the purchase of a “whip hose” to go along with the original hose. It’s a short, lighter hose that attaches to the original hose, and it just makes it easier to move around and use the gun, and I have found it to be less stressful on my (elbow) joints when I’m working on a big job.

I have recorded a video of me using the spray gun, but haven’t edited it to share (yet). Again, I said I was putting this sprayer post out there because I’ve been promising it for awhile, so bear with me friends.

Cleaning Your Spray Gun

The great thing about both of these sprayers is that they clean up the same way. For the most part, you just need to run warm soapy water through it once you’re finished spraying (you spray the water the same way you spray the paint). There is no need to completely take the spray gun apart every time you use it. If my sprayer isn’t putting out paint the way it should, I will take it apart a bit more and clean some of the vital parts (or replace them altogether).

I recommend having one of these cleaning kits because it really helps to get in the nooks and crannies when you’re cleaning. I use the brushes all the time.

Sometimes I soak the parts around the spray nozzle to make sure that I get all of the residual paint removed (when they get particularly gunky). Krud Kutter Brush Wash is a great, non-smelly cleaner that I have recently started using for both my brushes and my sprayer parts. It gets the job done, without all of the stinky fumes. That’s hard thing to come by these days. And, it cleans up after shellac and oil-based paints.

These are the parts I usually clean/replace if I’m having a problem (on both of these guns).

The Check Valve

The check valve goes between the gun cup and the gun itself, and has a tendency to get gunked up after a lot of use. Sometimes you can clean it and get it back in working order. Sometimes they just wear out and need to be replaced.

The Cup Gasket

These don’t have to replaced often, but if you have issues with paint leaking or bubbling out of your gun, and can’t resolve the issue with changing the settings, your cup gasket probably needs to be replaced.

The Nozzle

The last piece of equipment that I clean regularly is the nozzle (the piece in the middle of the photo below). Sometimes it can get plugged up if you’re doing a lot of spraying (and you don’t clean your gun right away – not that I ever do that…). Soaking it usually works (and this is where the brush also comes in handy, to make sure you get all of the residual paint removed).

The Needle/Projector Set

While we’re talking about the nozzle – it’s worth mentioning the needle, or projector set as it’s often called (the long metal piece on the left in the photo above, in case there’s any question). The HVLP Conversion Gun comes with a #1 projector set, which I used when I sprayed my cabinets. I also have a #2 projector set which I use often, and is geared towards heavier paints/primers. The Porter Paint primer that I use is pretty thick, so I like the #2 needle. Just something to consider – I don’t want you getting unnecessarily frustrated. I’ve already done the legwork for you. 🙂

Whew! There we go. I think we made it through the first installment. What do you think? What questions do you have? In my next round, I’m going to talk about sprayers that are more of the “all in one” type of functionality. As always, I appreciate your feedback and your patience for how long this has taken me to put together!

If you missed the other posts from the “Painter in Your Pocket” series, check them out here.

Painter in Your Pocket: Let’s Talk Finishes

Painter in Your Pocket: Painting Furniture

Painter in Your Pocket: Prep School

If there are other painting topics you’d like me to cover, please let me know – I’m here to help! I’ve had requests on prepping a kitchen for spraying – I will have to add that one to the list!

Jenny

Linking up:

8 Comments

MissyB

October 31, 2016 at 12:20 pmThank you for this post. It is SOOO helpful. I commented on your last post about a prep post, and now I see you already had posted one. Oops, somehow I missed it. Thanks again for all the great info. Wish I lived close, I would come spend the day with you painting!

Love your blog : )

Karen

November 1, 2016 at 1:09 pmJenny – this is GREAT!!! I can see why you’ve been hesitant to post this info – but WOW this is exactly the kind of info I’ve been looking for! I love the detail and have read it twice now, once w/my hubby, to digest it all, and will likely read it a couple of more times to make notes. The chart of the various spray pattern issues was really helpful to see also.

BTW – that Titan Capspray HVLP Turbine system is a beaut! We clicked on the link, and my hubby gasped, lol, but truly, I can see how this was an investment that has paid for itself over and over. Ahhh… I love those word “factory finish”. It’s right up there with “meticulous”. Lol…

Well done, brave Jenny…. 🙂 It was worth the wait and I look forward to the other posts related to the paint sprayer (and of course, your other posts).

As a possible post, I’d love to hear more of your story. How did you decide to go from corporate life to starting a business primarily painting furniture and kitchen cabinets? What was that journey like? Did you already know how to run a small business? I’ve been out of the corporate world for over four years and I don’t want to go back to dreading Mondays and having that sick feeling in the pit of my stomach starting Sunday evening. Starting a business out of something I enjoy may be the right direction.

Cheers!

Jenny

November 1, 2016 at 6:29 pmKaren, I’m so glad you found it helpful, and thank you for prompting me to just bite the bullet and put it out there. The Capspray HVLP turbine system is a beaut, isn’t it? 😉 I love it, and it really has been a great investment and one of my favorite tools. But again, the conversion gun is also a great tool for the price, and gives amazing results as well.

I will have to put some thought into my story, and thanks for asking! In a nutshell, my corporate job was taking over my life, with layers of management being added that didn’t make sense, and I was just miserable. I had been happy for much of my corporate time, but this was just ridiculous. My husband had been pushing me to quit, for awhile, and when push came to shove, it was much more difficult to give up my “identity” that was tied to my work, which surprised me. But, once I made the decision, it was like a huge weight had been lifted, and I’ve never regretted it!

My business grew from my own kitchen, to doing kitchens for friends, and then it’s just taken off from there. It’s been such a blessing, and I’m so thankful that I get to do what I love. I was just talking to one of my old work friends about this today, and said that I could never go back to working for someone else! As for knowing how to run a small business – I have a business degree and an MBA, but suffice to say, I’m learning as I go, and my husband is a big help as well. So far, it’s just me, so that makes it a little simpler, but I’ve been thinking that if business continues to grow that I will inevitably need to hire people, so that’s uncharted territory! But, it’s a great learning experience, and it’s so rewarding to have started something from scratch and grown it myself!

Debbie

November 2, 2016 at 3:10 amExcellent info but I am still a little chicken to try. I will start with baby steps. What kind of mask or respirator do you use, please? I hate the smell of paint.

Monique

April 30, 2017 at 10:33 pmHello,

I bought the Wagner spray gun and it worked wonderfully on the primer coats however on the final coats I have bubbles! Any ideas about why or how to fix it?

Jenny

April 30, 2017 at 10:34 pmAre you spraying Benjamin Moore Advance? I’ve never had that happen before! Did you thin it at all?

Kelsey

September 20, 2019 at 1:35 amWhen spraying Benjamin Moore Advance with an HVLP did you have to thin the paint? If so, what ratio/thinner did you use. Same with top coats and primers?

Jenny

September 20, 2019 at 3:21 pmTypically, I didn’t have to thin the Advance very much. I think the max it says to thin it is 10% – double check the can and see what it says, but I never had to thin it all that much. Primers I don’t thin at all, nor do I thin topcoats.